Sustainability?

I am transitioning from cone 10 reduction and salt firing to cone 6 oxidation because my long held dream of solar firing has now become practical. I worked on firing with direct solar energy years ago (see below) but this method remains difficult, you need a lot of hardware to fire a small kiln. The most practical method right now is solar panels tied to the grid. You sell energy to the electric company between firings and buy some of it back when you fire your kilns. Using storage batteries is also interesting and is likely to become affordable soon.

True sustainability is difficult and complex. There is a lot of hype. Carbon neutrality is often abused or misunderstood. The mission now is to find how we can do the best we can. What parts of the pottery making process use the most energy or otherwise disrupt the environment, and what can we do to remedy these? The energy for firing our kilns is significant but mining, processing and transporting materials also have impacts. What if we select a different material? I am analyzing these things to find out what works and what doesn't. I'll be publishing results as I have them.

Solar Kiln 1970's and '80's

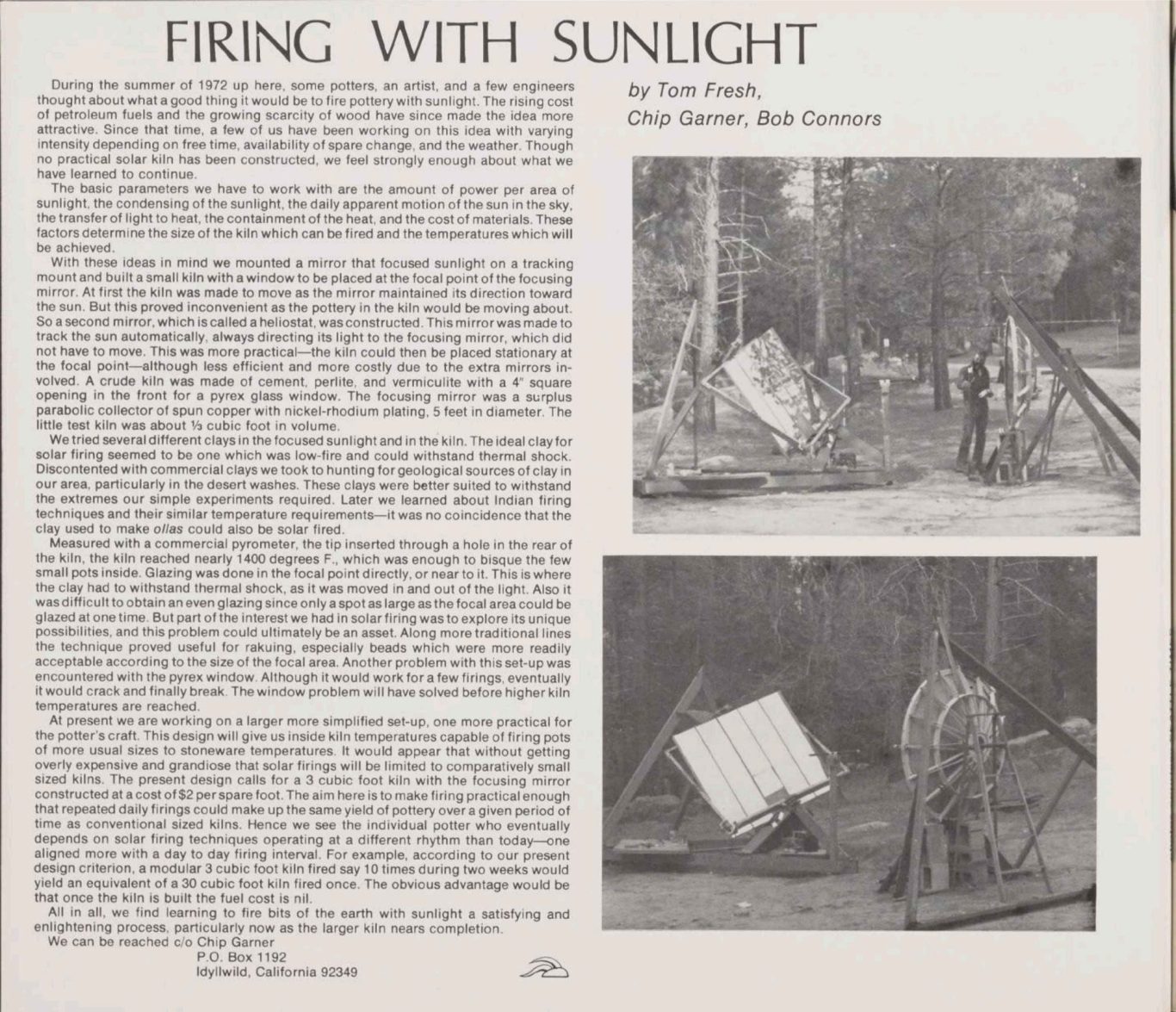

My first attempt at solar firing was in 1972 with Tom Fresh and Bob Connors. We made several attempts at constructing concentrating mirrors. We tried spinning a large plywood form filled with wet plaster on a potter’s wheel. The idea was to get it spinning at about the right speed for the curvature we needed and then hold the speed constant until the plaster hardened. It got off balance and fell over, taking the wheel with it and making a spectacular mess. The University of Arizona in Tucson uses the spinning technique, with molten glass, to make telescope mirrors. Their mirrors don’t fall over.

We also tried hanging a rock from a tree and swinging it to scoop out a spherical section. I picked a very stiff looking tree, but it moved with the wind and the motion of our pendulum and did not work at all.

Our final solar kiln is shown in the article below. We found a used metal reflector, I think for microwaves. We glued hundreds of one inch circular mirrors on the surface. Each mirror had to be aligned by hand, so we had to keep things pointed at the sun so you could see that the mirror you were gluing was pointed just right. We soon found this got too bright to look at and switched to aligning the mirrors in moonlight.

This is from Studio Potter, volume 4 number 2, published in 1975.

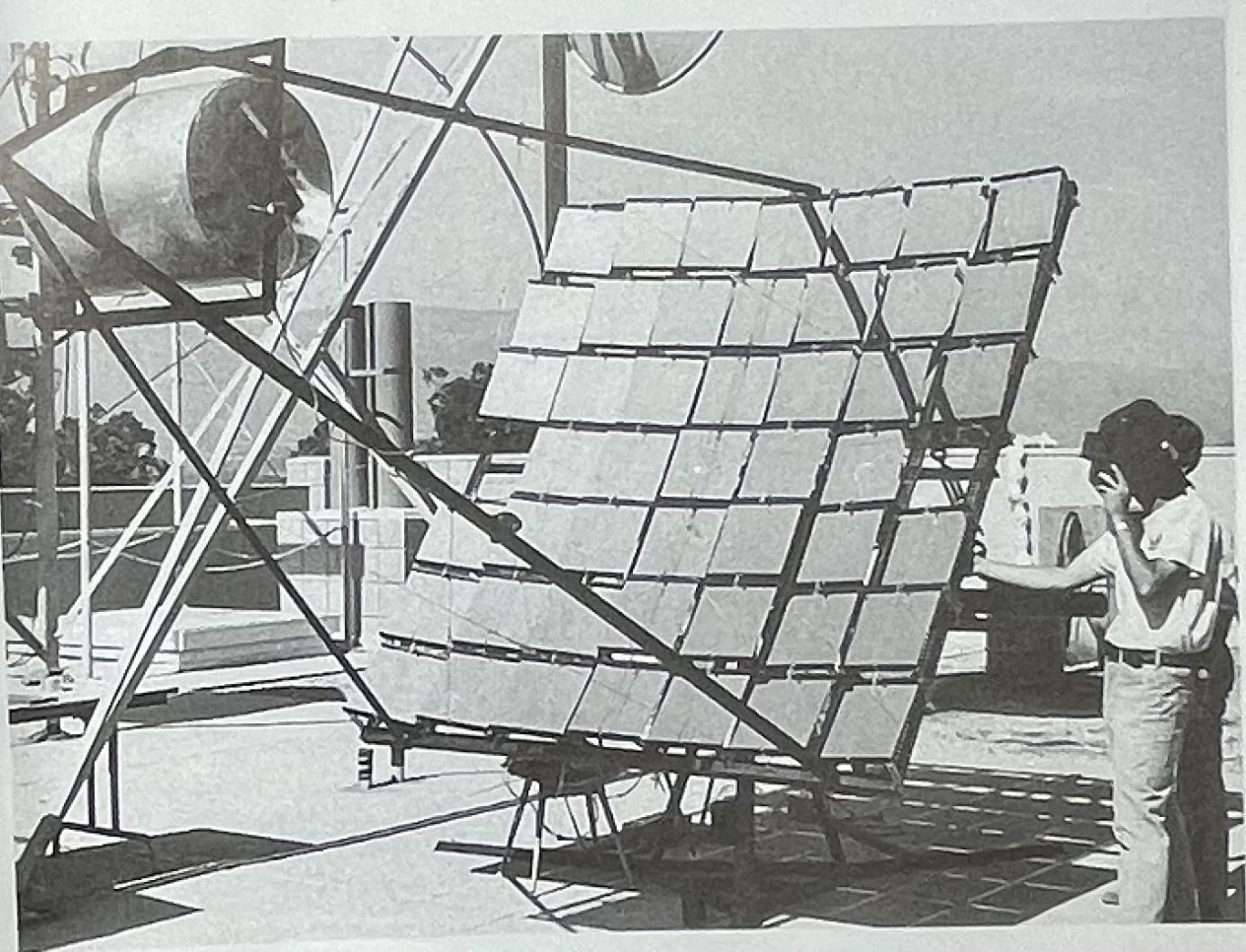

The next solar kiln was built in 1980 as a senior design project on the roof of the Engineering Building at the University of California in Santa Barbara. The team was Bob Asanuma, Corey Mayers, Chris Schuster, Willyanto and I. We fired this four times, unfortunately with no pots. The maximum temperature was 790C (1450F) when the pyrex window melted. The kiln volume was 23.4 liters (1.2 cubic feet). We fired with two silicon carbide slabs weighing a total of about 4 kg (9 lbs) to simulate heating clay. Tracking was manual, you had to stand there and watch the kiln with a welding mask as shown in the photo below. This demonstrated that firing low fire pottery with a solar kiln is possible.

The concentrating mirror consisted of 47 inexpensive square mirror tiles mounted on a tracking frame. Each mirror was bent slightly to focus a rectangle of light into the kiln through a pyrex window about 36 cm (14 inches) wide by 3.8 cm (1.5 inches) tall.

Photo by Virginia Garner

Harriet E. Brisson

Harriet did lot of work on firing pottery with direct solar energy around this time. She published several articles, two of which are listed here.

"Firing with Solar Energy" and "Alternative Fuels", Harriet E. Brisson, National Council on Education for the Ceramic Arts, Journal 1981, Volume 1, Number 1.

"Firing with Solar Energy" (Very similar to the article with the same name above.), Harriet E. Brisson, The Studio Potter, Volume 10, Number 1, December 1981.

©Copyright. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.